NCQ-Center of Certification and Quality

Under coordination by DQN, created in 2009

Internal service

Establish and maintain the quality management systems: As LECM is an organization providing reliable testing for construction materials of Macau and technical assistance to public and private sector in the field of civil engineering, to ensure the conforming product will only be used in construction project, and provide a trustable backup to public or private section of Macau society in civil engineering field, it is necessary to establish a quality management system which is applicable for LECM, NCQ of DQN is responsible for establishing and maintaining the quality management system and ensuring its’ effective implementation

Coordinate the 3rd party accreditation activities: For the quality management system which is being implemented, NCQ is responsible for coordination of ISO 9001 certification, ISO 17025 and ISO 17020 accreditation, ensuring the effective implementation of such management systems through certification/accreditation and regular assessment conducted by 3rd parties

External service

Conduct product certification and factory production control system certification

The norm such as concrete and cement which are formulated by LECM, is based on the cooperation scheme with DSSOPT, in order to effectively implement such norm and also to enhance the overall quality of construction materials in Macau market, according to 56/ SATOP/98, LECM is authorized by Macau government, to perform the following types of certification based on current norm and standard:

1. Product certification

2. Production control system certification

Introducing certification to product or production control system of factory, ensure the regular evaluation on quality management system and its product’s quality. Furthermore, it will benefit to other departments or centers when making a technical advice and analysis on the use of relevant manufacturers and its products.

Introduction of NCQ’s services

Internal services

Establishment and Implementation of ISO 9001, ISO 17025 and ISO 17020 For more than 35 years since the establishment, LECM has developed the internationally applicable quality management system (ISO 9001), management system for testing and calibration laboratory (ISO 17025) as well as the management system for inspection body (ISO 17020).

3rd parties ISO 9001 certification ,ISO 17025 and ISO 17020 accreditation

LECM has been successfully certified and by China Quality certification Centre (CQC) for ISO 9001 since 2006 and accredited by China National Accreditation Service for Conformity Assessment (CNAS) for ISO 17025 since 2007. Besides, NMT of DQN is accredited by IPAC since 2000 regarding accreditation on calibration laboratory (ISO 17025). Recently, LECM has been accredited by CNAS for ISO 17020 since 2023.

Internal Quality Management System Training

Other than the service of product and factory production control system certification, NCQ is also responsible for providing the training to laboratory’s staff regarding the quality management system and requirement of management system for testing and calibration laboratory, to enhance the awareness of such management system for integrating into laboratory’s operation and service provided.

Internal work forecast

Maintain the effective implementation of current management system, commence the establishment of management systems for ISO 14000 (Environmental Management System) and other fields of certification and audit.

Cooperate with other certification body, explore the certification project cooperated with Portuguese speaking countries.

Certificate of ISO 9001 issued by CQC

Certificate of ISO 17025 issued by CNAS

Certificate of ISO 17020 issued by CNAS |

NMT of DQN is accredited by IPAC regarding accreditation on calibration laboratory (ISO 17025).

LECM Quality Manual for Quality Management System

version of quality management system documentation of LECM is uploaded to LECM intranet

LECM Quality Manual for Testing/calibration

Training coordinated and provided by NCQ, to relevant colleagues from other departments/centers regarding the management procedures in laboratory

Training of management procedures includes the lecture on each procedure to colleagues from relevant departments/centers

External services

NCQ of DQN is responsible for coordination and implementation of certifi cation activities.

• Certifi cation of factory production control systems

• Certifi cation of products for the construction fi eld

Certifi cation of products

Certification of construction materials that used in Macau market according to the relevant Macau Standard;

It guarantees that the supplied products are in conformity with their specific standards. LECM certificates of cement and concrete are in accordance with the Cement Standard and the Concrete Standard of Macau, respectively. Besides, according to the dispatch from DSOP, LECM is authorized as a certification body for PHC pile product.

Certification of factory production control systems

It guarantees the producer’s capacity to supply products satisfying their specific standards, based on the ISO 9000 standard.

Construction materials and components from certified producers are subject to lighter rules of reception on the construction sites. Besides of the quality management system, the technical part of the certification work (including the certification of ready-mixed concrete, cement, PHC pile, certification of factory production control system for precast concrete pipes and manhole elements) is collaborated with DMC of LECM.

Product certification---Ready-mixed concrete

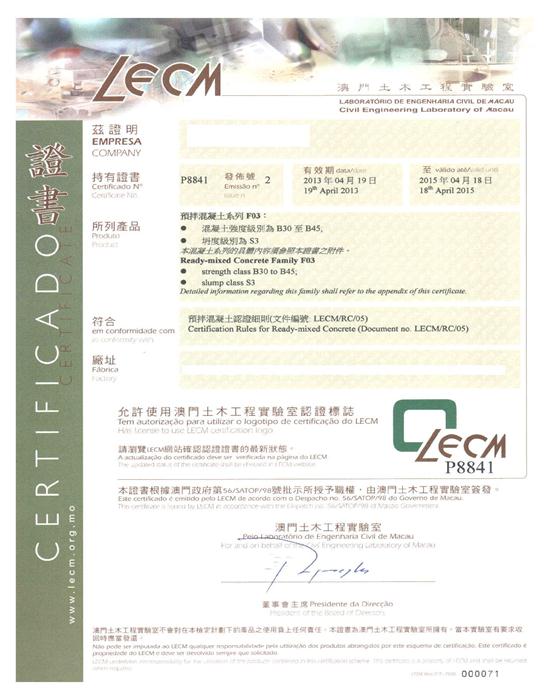

LECM is authorized by Macau government as a certification body for ready-mix concrete and established the “Certification Rules for Ready-Mix Concrete”. Up to end of 2013, there are 6 local batching plants are certified by LECM.

The recent established Macau ready-mixed concrete Association is composed by six LECM-certified concrete companies. Requiring LECM’s certification of concrete is taken into consideration for the entry requirements for the association.

The concrete with 100 year durability used in construction of Macau Light Rail Transit, are certified by LECM.

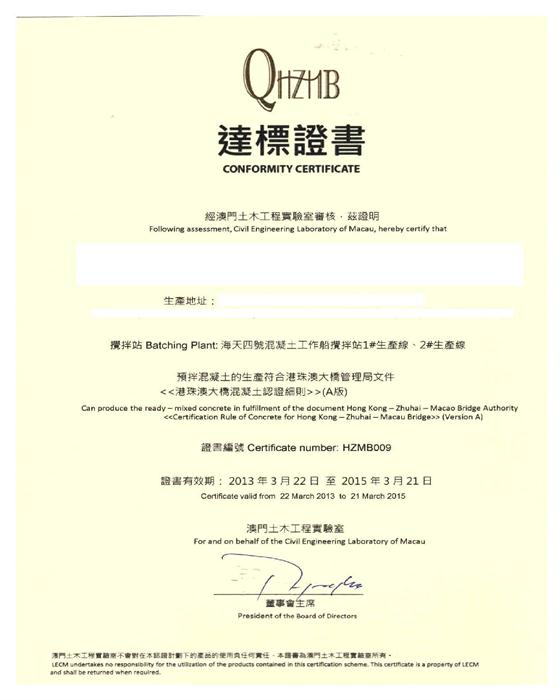

In 2012, LECM is commissioned by the Hong Kong-Zhuhai-Macau Bridge Authority, as a certifi cation body for certifying concrete used for the bridge. As of now, the concrete of the main construction including all batching plants used in Immersed Tunnel and Bridge structure have been certifi ed by LECM.

For the certified factory, LECM will conduct the quality management system audit , type test and conformity verifi cation in regular basis, in order to continuously evaluate the effectiveness of the implementation of quality management system and stability of quality of concrete product.

The onshore batching plants certified by LECM includes the local batching plants, batching stations in mainland used for Hong Kong-Zhuhai-Macau Bridge, batching stations for precast elements for Macau LRT project

Audit to offshore concrete batching ship, the quality management system audit is not only located on the ship, but also includes other supporting unit(or department) onshore.

Contract signature between LECM and CCCC for certifi cation of concrete in 2012.

Opening meeting during audit to factory

Audit to factory’s record of quality management system

Audit to factory’s concrete production control system, to determine whether the factory fulfi l the internal production control requirement.

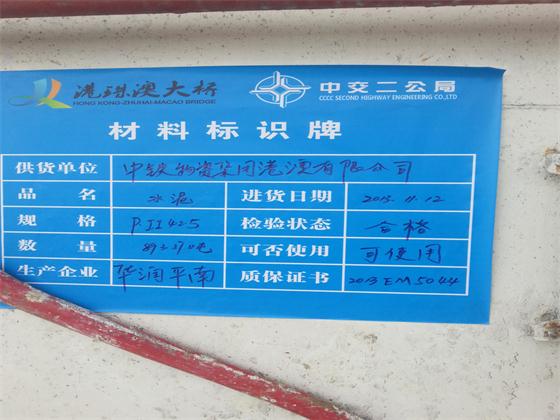

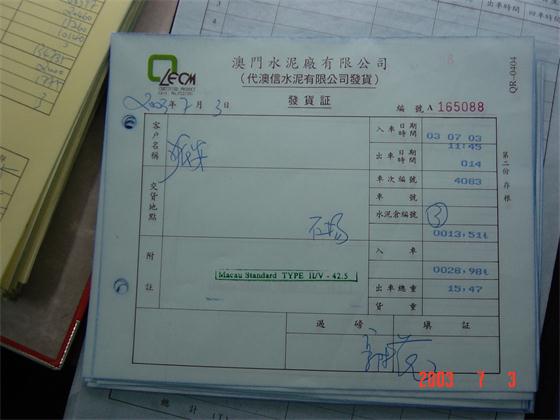

Check the identification of the raw materials, and trace back to supplier, method of purchase and record of logistics through the information shown, in order to check whether the factory fulfi l the internal requirement in terms of control of raw materials.

Inspection to maintenance work and its record for batching plant during the audit, to confirm whether the factory implement the internal requirement effectively

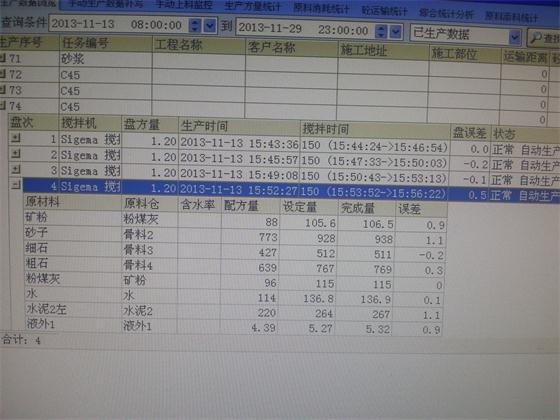

Checking on weighting accuracy, previous production record, input parameter and output results of concrete batching system, to verify the compliance with certifi cation and factory’s internal control requirements, during the quality management system audit.

meeting with factory reporting the audit result

Certifi cate for ready-mixed concrete

Conformity certificate for concrete used in Hong Kong-ZhuhaiMacau Bridge

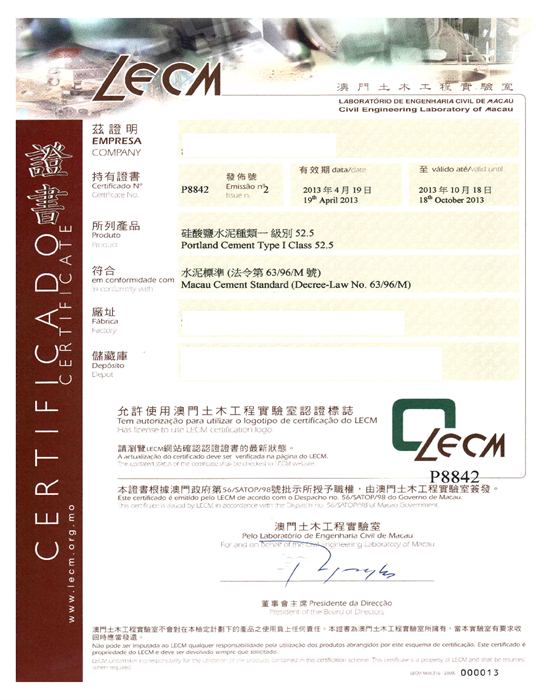

Product certifi cation --- Cement

LECM provides the product certification activities to cement manufacturer for cement products, based on the Macau government’s approved rules of scheme for certifi cation of cement. For the certified cement factory, LECM will conduct the regular surveillance audit, and perform sampling in factory, depot (if use), local market, in order to continuously evaluate the stability of cement quality.

As of now, the certified cement manufacturers located in Guangdong, Guangxi and as far away as Japan.

manufacturers of cement including cement grinding station or clinker-cement production

Inspection to pre-homonegization process control for raw materials of cement

Quality System audit to factory

Audit to clinker production system in factory

Audit to clinker production system in factory and the operator, evaluate the his/her capability of satisfying the production requirements

Audit to cement grinding system, to confi rm whether the factory comply with the internal quality control requirement.

Audit the operation status of cement grinding system.

Audit to testing laboratory in factory, check the documentation and record.

Audit the delviery record for bulk cement, to check the compliance with quality management system requirement.

Audit the control system for packaging line of cement

Audit the quality management system implemented in cement depot

Certifi cate for cement

Product Certifi cation---Pre-stressed High strength Concrete (PHC) Pile

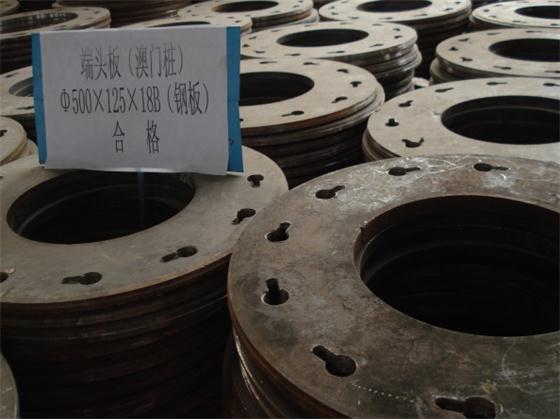

LECM is authorized by Macau government as a certifi cation body for pre-stressed high strength Concrete pile product, and established the “Certifi cation Rules for PHC piles”. Until end of 2013, 6 PHC pile manufacturers all located in Guangdong are certifi ed by LECM. For the certifi ed PHC pile factory, LECM will conduct surveillance audit to the factory regularly, which includes the evaluation of effectiveness of the implementation of factory quality management system, the stability of quality of PHC pile product and its raw materials. Besides, LECM will perform sampling in factory, local market or construction site.

Quality Management System audit to PHC pile factory

Audit to concrete production control system in PHC pile factory

Audit to fabrication control system for steel cage, inspection to steel cage fabrication

Audit to concrete distribution system, to check the compliance with the internal production control requirement

Inspection to moulding, check the compliance between the workmanship and the internal requirement for moulding

Audit to pre-stressing control system, check the workmanship when preforming pre-stressing and factory’s self-verifi cation on elongation of reinforcements

Audit to control system of centrifugation for PHC piles

Audit to control system of steam curing, check the compliance between the parameters (i.e. temperature and time) and internal work instruction of factory.

Audit to Autocave curing control system

Check status of storage for PHC pile fi nal product

Inspection to end plate and its identifi cation.

Check concrete cover of a core from selected pile

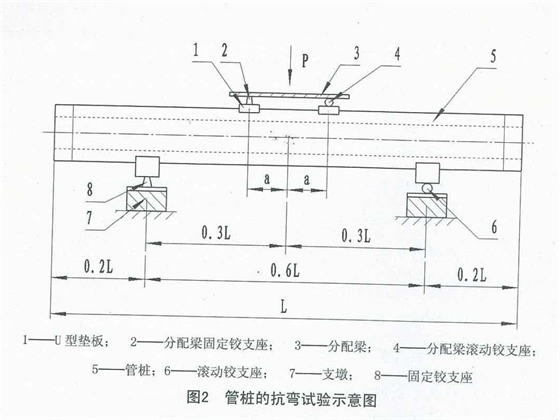

With reference to GB 13476-2009 <<Pretensioned spun concrete piles>>, bending test is also required in LECM <<Certification rules for PHC piles>>.

Certifi cate for PHC pile issued by LECM

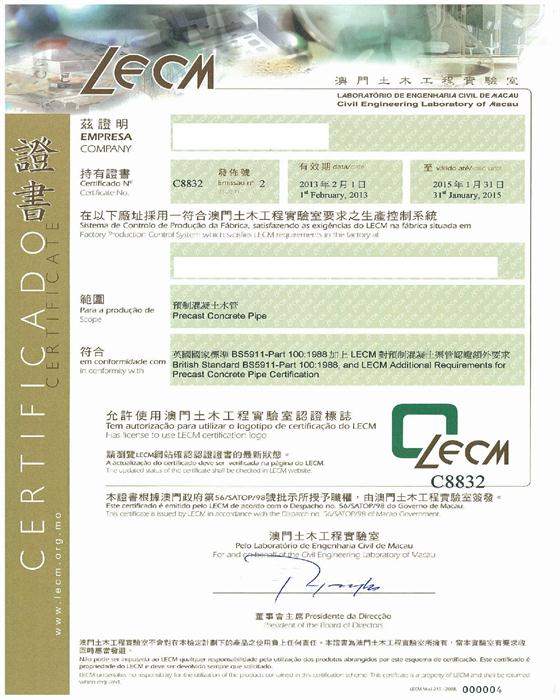

Factory Production Control system certifi cation---Precast concrete pipe and precast manhole element

LECM Provide Certification of factory production control of construction materials that used in Macau market according to the relevant Macau Standard, including, concrete pipe and manhole fittings. For the certified factory, LECM will conduct regularly the audit to the factory production control system, to evaluate comprehensively whether the factory can consistently fulfil the quality assurance requirement and relevant product specification. As of now, there are two factories certifi ed by LECM for the factory production control system.

Certification of FPC system including production of precast concrete pipes

Certification of FPC system including production of precast manhole elements

Inspection to storage for raw materials and its quality control

Inspection to the steel cage fabrication system

Check the control system of steel cage fabrication and quality of the steel cage for precast concrete pipe

Inspection to concrete production control

Inspection to curing control system

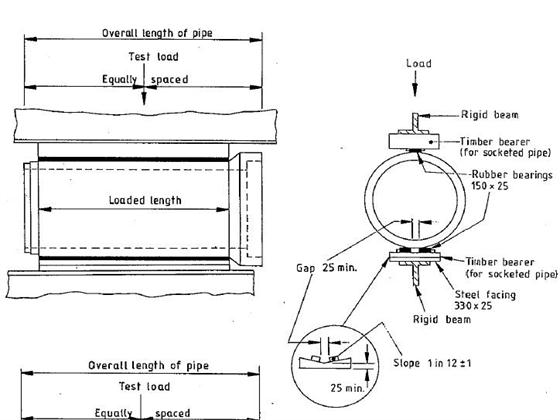

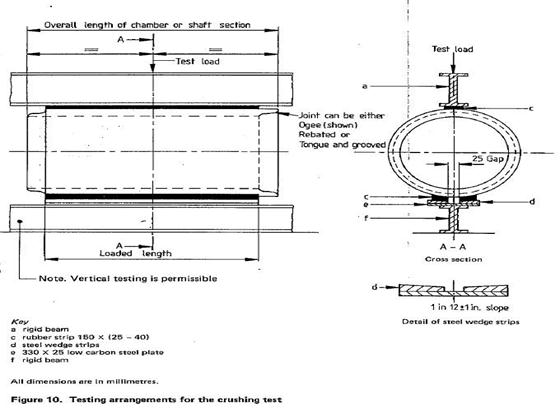

Perform mechanical test on precast concrete pipes, based on the requirements in BS 5911 Part 100:1988 during the audit to factory’s production control system

Perform Hydrostatic test on precast concrete pipe, based on the requirements in BS 5911: Part 100: 1988 during the audit to factory’s production control system

Inspection to production process of product

Perform mechanical test on precast concrete manholes, based on the requirements in BS 5911 Part 200:1989 during the audit to factory’s production control system

Certifi cation of FPC system issued by LECM

External work forecast

NCQ will focus on develop the extension of product certifi cation to other construction materials