NSP - Center of Soil and Pavements

Structures of Center of Soil and Pavement

Center of Soil and Pavement (NSP) is a service unit under Geotechnical Department (DG), we offer testing analysis of soils and pavement material, inspection of (airport) pavement and underground utilities for the customer of Macau and a growing international client base, to provide them an accurate and timely reports to meet the unique requirement of civil engineering, geotechnical engineering and (airport) pavement engineering

Soil Classifi cation

Soil classifi cation is fundamentally important to any geotechnical engineer. It provides a common language to concisely express the general characteristics of soils, which are infinitely varied, without detailed descriptions. Currently, two more elaborate classification systems are commonly used by the engineers. They are the American Association of State Highway and Transportation Officials (AASHTO) classification system and the Unified Soil Classification (Unified system) System. Both systems take into consideration the results of particle size analysis, Atterberg limits etc. LECM provides particle size analysis, moisture content, Atterberg Limit, void ratio, specifi c gravity of soil etc.

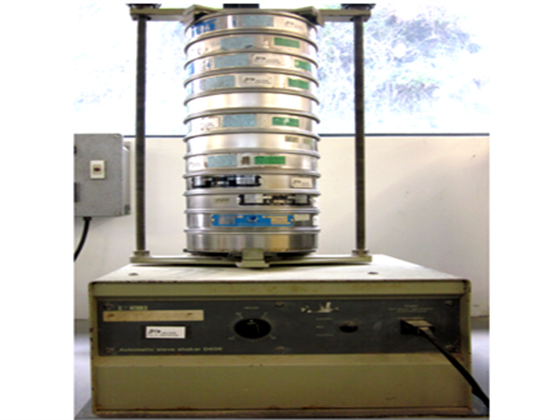

Particle size analysis

Particle size analysis

Moisture content

Atterberg limit

Specifi c gravity

Quality of Soil Engineering

The quality of civil engineering construction such as foundation, retaining walls, dams, (airport) pavement and improvement of backfilling etc. afterward must be assessed by verification test, to know such as the density, settlement characteristic, bearing capacity etc. LECM has participate those reception tests for Macau government, and provide soil compaction test, soil relative density test, fi eld density test, interior/fi eld CBR test, interior soil permeability test to the public etc. In future, more advanced, quickly and portable types of test will be introduced in evaluation of soil compaction / soil bearing capacity depending on their feasibility and applicability in Macau Civil Construction. Such as non-nuclear fi eld density gauge, dynamic cone penetrometer test to evaluate the CBR of subgrade soil portable, quickly and non-destructively

Modified Proctor compaction test

Relative Index density test

Field density test

Interior CBR test

Field CBR test

Interior soil permeability test

Field Dynamic Cone Penetrometer (DCP) test

Non-nuclear soil density test

Soil Mechanic

Geotechnical engineering was necessary to investigate the physical properties of different types of soils, just as it was necessary in structural engineering to investigate the properties of steel and concrete, etc. However, unlike steel and concrete, practical problems involving soils may require the consideration of a variety of soil properties, such as the permeability, the resistance against shear, and the stress-deformation relationships, etc. LECM has involved those kinds of test in site investigation for Macau government project. In field and laboratory test, LECM provides direct shear tests, laboratory / fi eld vane shear test, unconfi ned compressive strength test, soil permeability test, etc. Besides that, LECM provides the advanced test such as, triaxial compressive strength tests, 1-D consolidation test etc. In future, more advanced and automatic data logging system will be involved in testing the physical properties of soil.

Direct shear test

Field vane shear test applied for dredging

Interior vane shear test

1-D consolidation test

Unconfi ned Compressive / Triaxial compressive strength test

Soil permeability test

Bearing Capacity of Soil

In foundation engineering, the soil must be capable of carrying the loads from any engineered structure placed upon it without a shear failure and with the resulting settlements being tolerable for that structure. It is necessary to investigate both base shear resistance and settlements from any structure. Beside soil laboratory test to evaluate the mechanical properties of soil as described in previous section, it is obviously that the most reliable method for obtaining the ultimate bearing capacity at a site is to perform a fi eld load test. This would directly give a bearing capacity if the load test is on a full-size footing. LECM provides fi eld plate load test, lightweight dynamic penetrometer test to investigate the bearing capacity of shallow foundations, airport / road pavement etc. In future, dynamic plate load test, automatic data logging would be introduced to monitor the long term stress-deformation relationships of soil depending on the depending on their feasibility and applicability.

Field plate load test

Lightweight dynamic penetrometer test

Quality of Bituminous Material

The quality of bituminous material is important to producing qualified bituminous concrete mixture for (airport) pavement. Using the correct grade of bitumen insures that the pavement will perform as expected under the conditions encountered in the field. Therefore, other than the grading of mixture, the grade of bitumen characterizes the performance quantitatively, in order to comply with the requirement of climate, traffic and construction serves etc. to fulfill the performance and durability in pavement construction. Traditionally, penetration, softening point, ductility, fl ash and fi re point of bitumen are the major parameters to describe the characteristic of bituminous material. LECM provides all of the services to the Macau government. In coming future, with the application of different design methodology of bituminous concrete mixture with application of different grade of bitumen, further comprehensive and advanced grading test would be introduced, such as penetration index, viscosity to optimize pavement construction.

Penetration test

Softening point test

Flash and fi re point test

Ductility test

Quality of Bituminous Mixture

Quality control of bituminous concrete mixture is to provide the traveling public with an adequate and economical pavement on which vehicles can move easily and safety from point to point. The control process of hot-mix bituminous concrete mixture becomes important to ensure their quality. For continuously improvement of bituminous concrete pavement of Macau, LECM always works with Macau government in quality control of bituminous concrete mixture with field sampling, interior and field reception test to study the both the mechanical and fi eld performance of mixture. To qualify the high-temperature performance of bituminous concrete mixture, rutting susceptibility of bituminous concrete mixtures is introduced and would be serving to the public soon. In future, more test items would be introduced in the Macau such that the more comprehensive performance of bituminous mixture can be evaluated, such as indirect tension test for resilient modulus of bituminous mixtures, resistance of compacted asphalt mixtures to moisture-induced damage, quick non-destructive non-nuclear density gauge for bituminous mixture in fi eld.

Supervision of bituminous concrete mixing material and construction

Supervision of bituminous concrete mixing material and construction

Sampling of bituminous concrete mixture

Supervision of bituminous concrete mixing material and construction

Quantitative extraction of bitumen of bituminous concrete mixture and Particle size analysis

Density and Thickness of compacted bituminous concrete mixtures

Flow and Stability test of Marshall test

Theoretical maximum specifi c gravity and density of bituminous concrete mixtures

Skid resistance test

Rutting Susceptibility of Bituminous concrete mixtures

Non-destructive density and thickness of compacted bituminous concrete mixtures

Airport Pavement

Pavement Classifi cation Index

The PCI is a numerical indicator that rates the surface condition of the airport pavement. The PCI provides a measure of the present condition of the pavement based on the distress observed on the surface of the pavement which also indicates the structural integrity and surface operational condition (localized roughness and safety). Continuous monitoring of the PCI is used to establish the rate of pavement deterioration, which permits early identifi cation of major rehabilitation needs. The PCI provides feedback on pavement performance for validation or improvement of current pavement design and maintenance procedures.

Visual inspection of airport pavement

Visual inspection of airport pavement

Underground Utility Survey

In Macau, spaces are limited in nature for underground facility construction such as electricity distribution, natural gas, water mains, storm drains, wastewater pipes, cable television, fi ber optics etc., so that the qualifi ed construction works are always challenges in either of planning and construction. Nevertheless, the destruction of underground facilities is happened in sometime who affect the public, safety of the workers, even in stability of existing’s or neighborhoods. Therefore, locating specific pipes or cables in large underground networks is becoming increasingly client base. Geophysical surveying techniques become the first priority to provide a toolbox of rapid, discrete and cost-effective methods for locating and identifying subsurface features. LECM has involved the work of geophysical surveying by GPR since 2008 with the Macau government. It provides a non-intrusive and non-destructive method of surveying the subsurface and concrete imaging. Not only is ground radar a highly cost effective non-disruptive technique, it is also a rapid means of obtaining subsurface information, such as concrete imaging and re-bar mapping, geo-profiling, identifying the voids, etc. In coming future, cable and pipe locator would be introduced to locate specific pipes and cables in even large and complicate underground networks more quickly and accurately.

Underground utilities survey in by trial pit excavation

Water leakage during construction

Underground utilities survey by NDT

Underground utilities survey in Macau airport by NDT

Underground utilities survey in Macau by NDT

Underground cable or pipeline survey by NDT

Underground cable or pipeline survey by NDT

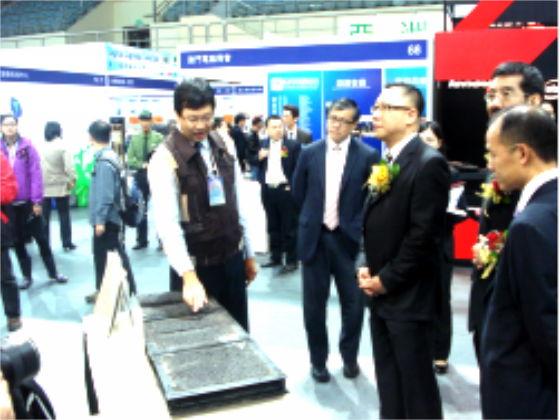

Research of Science and Technology Development Fund of Macau

The research mainly through theoretical calculations (mechanical model of finite element analysis), indoor model test (Automatic Asphalt Pavement Analyzer, AAPA to evaluate the fatigue performance of bituminous concrete mixture, Multi Rounds Rutting Tester, RLWT to investigate the behavior of Marshall specimens / pavement core specimens on high temperature conditions (60 o С), Multi Rounds Loaded Rotating Wheel Rut instrument, RLWT, Immersion Marshall test, Freeze-thaw Splitting test, Low Temperature Bending test) and demonstration projects, to deeply study of the engineering technology to minimize the reflective cracking overlay. Furthermore, this research is to improve bituminous concrete overlay fatigue performance (crack resistance) and high resistance to deformation against the climate, environment and traffi c characteristics of Macau, and to balance the contradiction between other properties, and to optimize the overlay structures and materials. Through this research analysis, the overlay technology under the formation of the old cement concrete was completed. In July 2012, the application of these fi ndings is applied in demonstration projects in Macau, so far, inspection show that the pavement performance is excellent, early disease phenomenon was not found.

4cm SBS Modifi ed Bituminous Wearing Course AC-16

5cm SBS Modifi ed Bituminous Medium Course AC-20

3cm SBS High Elastic Modifi ed Bituminous Base Course AC-5

Exhibition of Research in IT Week 2012