NIEE - Center of Buildings and Structures Inspection

BUILDINGS

Building structures could be affected by external factors, such as nearby foundation construction, excavation, vibration, and environment etc. Moreover, buildings will gradually deteriorate along their ages without proper maintenance, building defects will occur such as concrete spalling, steel reinforcement corrosion, deformation and cracking, water leakage, façade delamination, etc. Hence, DEE provides technical services including building structural inspection & monitoring, building public component inspection, building water leakage inspection, and aluminum window testings.

Building Structural Inspection & Monitoring

To evaluate the structural condition of buildings, visual inspection is an essential and fundamental step. Besides visual inspection, non-destructive tests will be performed to obtain scientifi c data so as to allow a more competent assessment. To evaluate mechanical properties of concrete, taking cores for compressive strength test, rebound hammer tests are the common practices. To evaluate the durability of the structural element, halfcell potential measurement, chloride content determination, carbonation tests, covermeter for rebar location and petrographic analysis will be performed. More new types of NDT will be studied on their feasibility and applicability in structural inspection.

Ultrasonic Test of Concrete Beam

Taking Concrete Cores

Half-Cell Potential Measurement for Concrete Structures

Taking Concrete Powder for Chloride Content Determination

Crack Size Measurement

Rebound Hammer Test on Concrete Slab

Steel Reinforcement Bar Locating with Covermeter

Tensile Load Test of Anchor Bolts

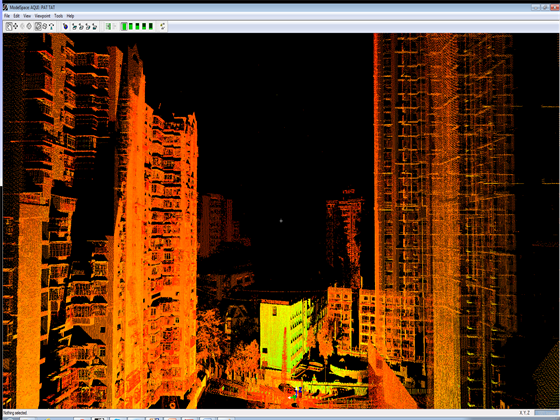

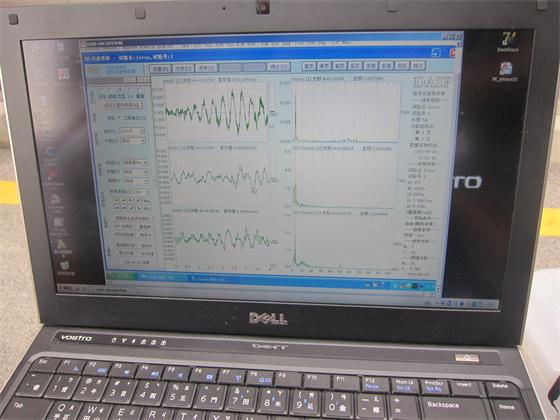

When building structural problem exists, or whenever there are site works near to the existing buildings, structural monitoring is an essential activity to be carried out, especially during piling, demolishing and excavation. Building inclination, foundation settlement, crack or joint width of a building, and ambient temperature will be the main monitoring data to be obtained so as to trace any tendency of structural problem development. Automatic monitoring system will be the major development in the coming future. Moreover, 3D Laser Scanning will be adopted more and more in the field of building monitoring in which millions of measurement (point cloud) allow more complete and accurate measurement of the deformation of a structure. Vibration measurement is also important to monitor the vibration effects on the existing buildings.

Inclination angle monitoring with Tilt Plates and Portable Tiltmeter

Inclination angle monitoring with Tilt Plates and Portable Tiltmeter

Installation of equipment for joint width monitoring between buildings

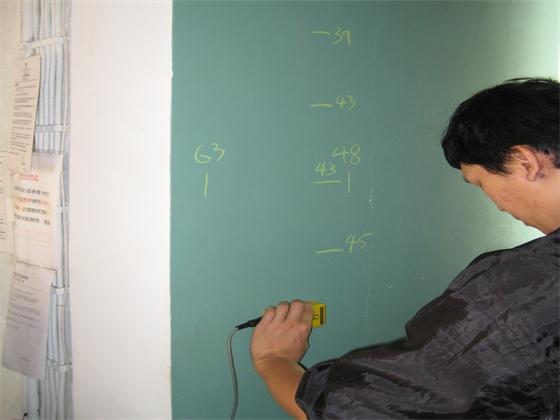

Joint width monitoring with electronic joint meter

Inclination monitoring of a column with electronic clinometer

Ambient temperature monitoring with electronic temperature sensor

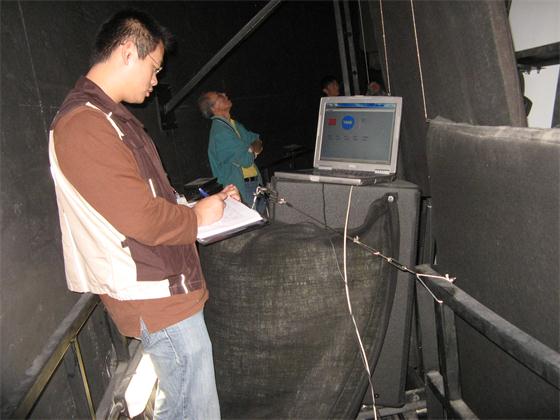

Automatic Monitoring System with datalogger and data transmission system

Crack width monitoring with electronic crack meter

3D Laser Scanning of Buildings

Inclination angle measurement by 3D Laser Scanning Method

Vibration Measurement of Pile Driving

Vibration Measurement of Pile Driving

STEEL STRUCTURES

Steel Structures are common types of structures adopted by structural designers, such as stadiums, swimming pools, monuments, etc. Corrosion, welded joint defects, crackings and deformation are the most common problems occur in steel structures. Besides of the quality consultancy service on new steel structures construction projects, DEE also provides technical service on steel structure inspection and load capacity evaluation.

Quality consultancy service

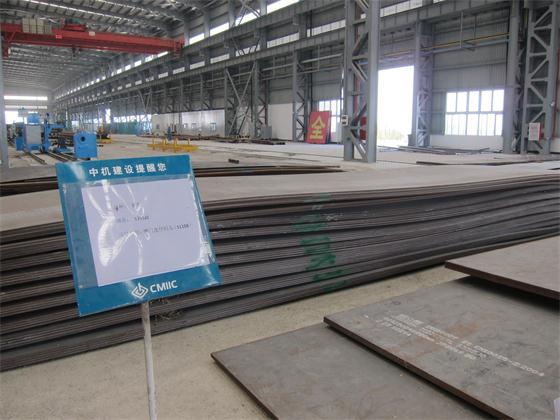

DEE has prepared MCQ and ARP of steel structure works, mainly to provide quality control procedure for the public projects. Inspection to steel factory is an essential activity to verify the implementation condition of quality control works in that factory, in terms of material control, fabrication control, welding control, coating control and delivery control.

Steel Material Control in Factory

Welding Process in Factory

Fabrication in Factory

Steel Components before Delivery

Steel Structure Inspection

DEE provides inspection to evaluate the structural condition and the durability condition of steel structures. Corrosion situation could be identifi ed by visual inspection and verifi cation of the corroded steel section thickness can be performed with ultrasonic thickness gauge. As good welding works ensure a safe and good quality connection between steel structural members, welding inspection is essential to ensure the quality of the welding joints. Besides traditional NDT such as Magnetic Powder Inspection (MPI) and Ultrasonic Test (UT), LECM has introduced Eddy Current Inspection, by which the defects of the joints of an existing steel structures (such as surface fatigue cracks) could be inspected without the complete removal of the surface coating.

Arco do Oriente

Platform for Inspection of Arco do Oriente

Inspection of Steel Structures

Bamboo platform for Inspection of Steel Structural roof

Welding joint inspection

Welding joint inspection

MPI for steel section joints

MPI for Steel Bar Cages of Bored Piles

UT for Steel Stair Cases

UT for steel section joints of Diaphram Wall

Eddy Current Inspection

Welded Shear Stud Inspection

Load Capacity Evaluation

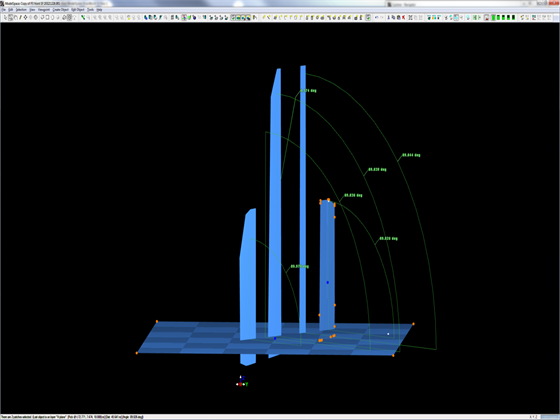

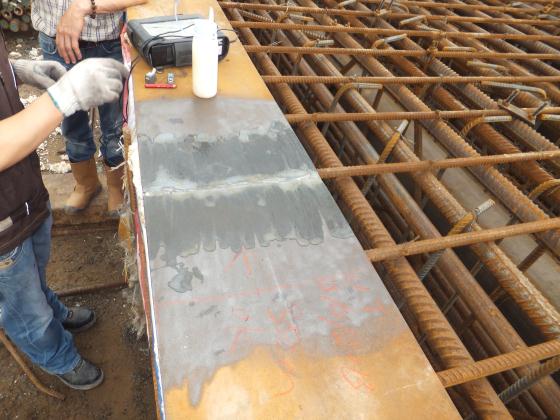

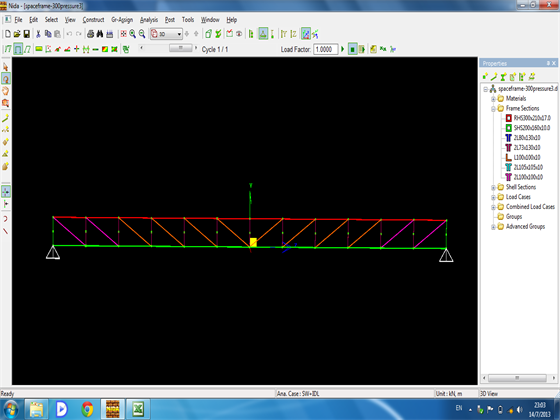

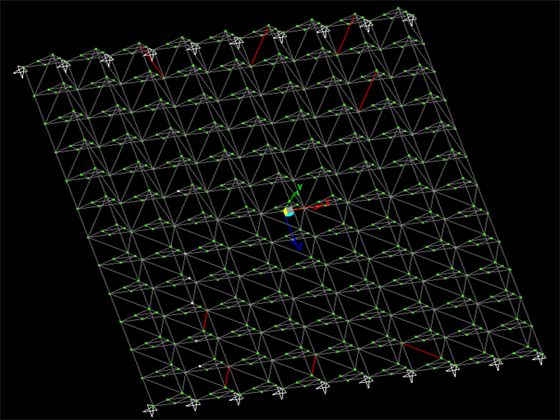

Load capacity evaluation could be carried out with on site structural loading test together and structural numerical model simulation. By measuring the deformation or stress/strain with the applied load on the targeted structural members, the structural behavior or any design assumption could be verifi ed. Moreover the structural numerical model could be calibrated by the loading test results so as to provide more solid structural assessment.

Hanging load test of steel space frame Structure

Loading application to the steel structure

Numerical Model Simulation

Numerical Model Simulation

Loading Sand Bags applied on the steel structure

Deformation recording

Deformation measurement with digital gauges